Synthetic Fiber Palm Tiles

Fiber Palm Is The Most Economical Synthetic Fiber Palm Tiles Covering Material In The World - Requirement - Only 3.2 Tiles Per Square Meter

Synthetic Fiber Palm tiles offer more to customers and have become a popular choice after the unbelievable worldwide success of Fiber Thatch Synthetic tiles that was achieved with Fiber Reed Synthetic. This range of synthetic thatch was developed to cater to the resort developers needs. On top of this, it has allowed resort developers the opportunity to find a long-lasting top-quality synthetic thatch.

Fiber Palm tiles not only look 100% natural but are of superior quality and durability all wrapped in a super economic option. The backbone of the Ocean is the 25 years of experience and impeccable reputation associated with Fiber Roofing’s synthetic thatch. However, the new style and composition of the Synthetic Fiber Palm had to be authentic in appearance, easy to install, durable, economic and trustworthy.

Fiber Thatch has designed a product that is just that, offering more to customers while being a cost-effective solution.

With Value For Money Is Unbeatable And Unmatched With Synthetic Fibre Palm

We are extremely proud of the newest addition to the Fiber Roofing synthetic fiber palm thatch family - thatched gazebos, African hut, and the Fiber Palm tiles. This unique synthetic thatch option has had a remarkable success story, with numerous resorts successfully supplied and completed within the last five years, covering well in excess of 300,000 m² of roof area. Making thatch roof construction quick and easy.

With great reviews, we have been able to push the Synthetic Fiber Palm product forward with even more triumphs to come ahead. This unique synthetic thatch option is different from all other options worldwide and caters to the full spectrum of synthetic thatch roofing.

We have a specialized edge, bushy, and ridge tiles, that in combination with the standard tiles, provide and tick all the required boxes. Using various combinations, all styles of thatch finish can be achieved.

Fiber Thatch also undertakes turnkey projects for the refurbishment of the world’s top resort destinations.

View our Synthetic Fiber Palm products below!

Fiber Palm Products

Fiber Palm mainly come in two colours, Bali and Makuti.

At Fiber Thatch we can custom make the perfect colour for you.

Fiber Palm Tiles

-

Product Information

Size: 800 mm (32”) x 650 mm (24”) x 6 mm (¼”) to 12 mm (½”)

Weight: +/-1.1 kg

Product Code: FPIO

Description: The Palm tiles are designed to be used over a sub-roof, such as Fiber MO Board, waterproofed plywood or even spaced wooden battens. The Fiber Palm tiles will provide the most realistic thatch roof finish and a major benefit of ZERO maintenance.

-

Container Information

Box size: 670 mm x 810 mm x 210 mm

Quantity Per Box: +/- 26.5 kg

Volume Per Box: 0.1153 m³

20 ft Container (33 m³): 286 boxes

40 ft Container (67 m³): 580 boxes

High Cube 40 ft Container (76 m³): 660 boxes

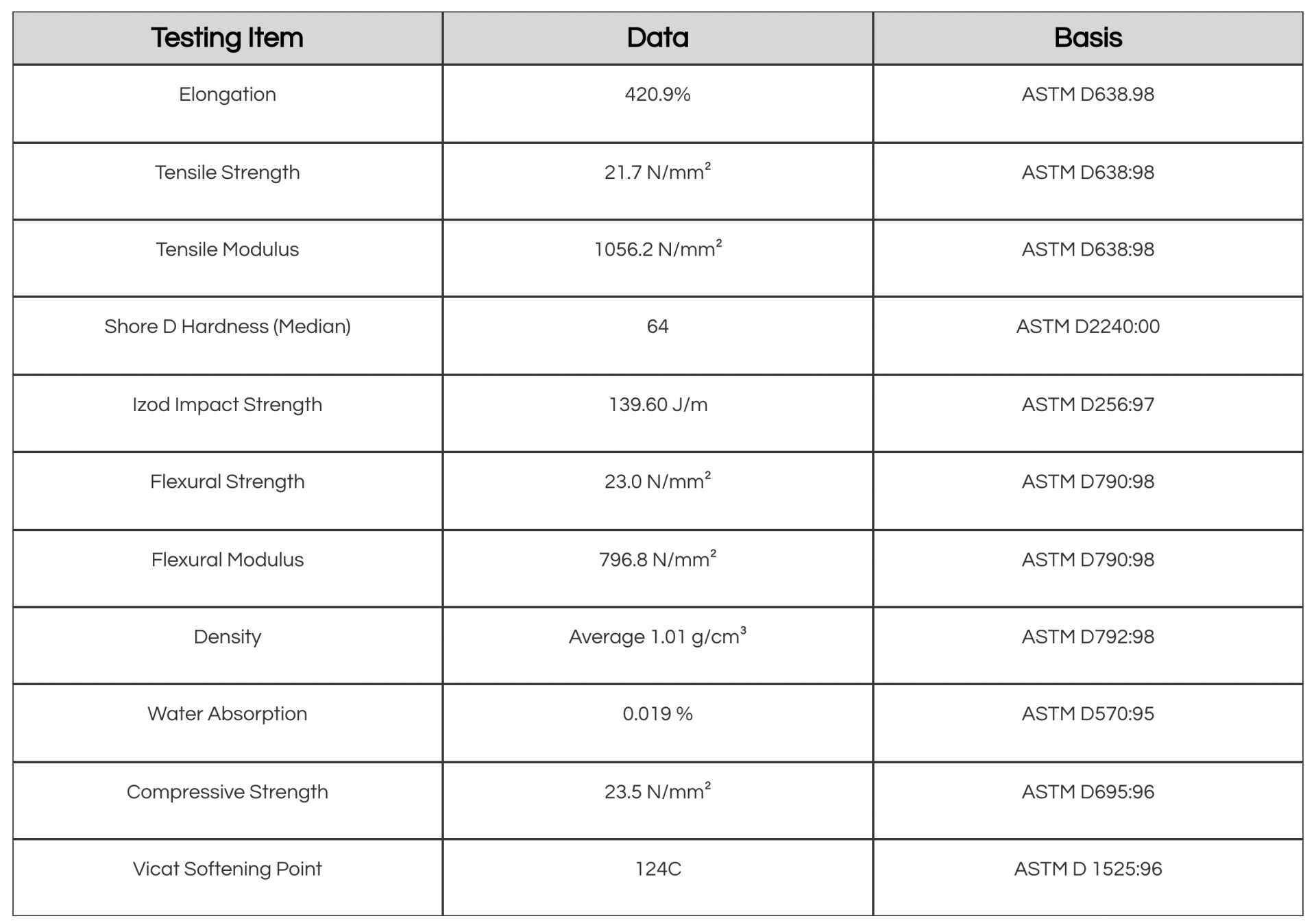

Technical Data

Easy To Install

We constructed a sample frame using Synthetic Fiber Palm, incorporating elements of thatched gazebos, African hut aesthetics. Note that the binding strips on the tiles can be spaced so far apart that the tile is only stapled onto every second batten. The spacing of the binding tiles can also be adjusted to accommodate branding spaces on existing roofs.

-

1: The constructed sample frame.

Button -

2: We stapled a Fiber Ocean (Fiber Palm) bushy tile at the bottom onto the frame

Button -

3: Following above the bushy tile we staple a Fiber Ocean (Fiber Palm) edge tile, to round off the ends.

Button -

4: Placement of the exterior tiles as you see on the inside of the frame.

Button -

5: Above the edge tile we staple a standard Fiber Ocean (Fiber Palm) tile.

Button -

6: We continue applying the Fiber Ocean (Fiber Palm) tiles to cover the rest of the roof surface up to the ridge of the frame.

Button -

7: A FR-MO Board is then placed on top of the ceiling tiles.

Button -

8: The waterproofed FR-MO Board is screwed onto the frame.

Button -

9: We repeat the process again. Starting off with bushy tiles followed by edge tiles.

Button -

10: We then continuing with the standard Fiber Ocean (Fiber Palm) tiles to the top of the frame, covering the rest of the roof.

Button -

11: See the sample board lifted up by Danie, Dawie and some members of our team to show the bottom and top.

Button -

12: Our goal to get the same “inside” and “outside” look has been achieved.

Button

Get A FREE Quotation from Fiber Thatch Today!

Custom Colours

Our Synthetic Thatch Product Can Be Matched And Customised To Any Colour That The Project Might Require.

We can manufacture our synthetic bali thatch in any colour you desire, we could match a prescribed colour brief 100%.

Fiber Thatch has the technology and ability to custom design a specific colour for a project. We have successfully colour matched natural thatch in many different locations all over the globe.

We are often requested to blend a specific colour brief to match a desired look that architects or designers need for their projects. We are confident that we can match any colour desire and effect that might be required. Our many strange coloured successfully completed projects speak for themselves and are a great testament to this claim.

This fake / mock thatch looks like an original palm roof, with the benefit of

environmentally friendly

100% recyclable material and low maintenance. Your Bali or African Tiki hut will look gorgeous and last years.

Custom Colours We Have Done

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Contact Fiber Thatch Today

Thank you for your interest in our exclusive Fiber Thatch products.

Whether you already know exactly what you’re looking for, or just want some ideas and approximate price for your project, please fill out the form and our sales manager will contact you for a free quotation.

We have distributors all over the world and will put you in touch with them.

Head Office:

Phone: +27119039204

Email: info@fiberroofing.com

Plot 22 Of Section 35, Old Vereeniging Road, Kliprivier, 1836

MON-FRI 08:00 - 17:00 - Central Africa Time

Fiber Palm Contact Us

We will get back to you as soon as possible

Please try again later

- Mon - Thu

- -

- Friday

- -

- Sat - Sun

- Closed

our locations

Head Office

Phone: 011 903 9204

Email: info@fiberroofing.com

All Rights Reserved | Fiber Thatch | Privacy Policy

All Rights Reserved | Fiber Thatch | Privacy Policy